Breather Valve is also known as direct-acting Pressure/Vacuum Relief Valves are special kinds of Relief Valves that are specially designed to protect tanks.

The range comprises vacuum only, pressure only, and combined Pressure and Vacuum Valves each with flanged outlets, or vented to air.

Top-quality breather valve manufacturers in India. Reliable, efficient, and customized solutions for your industrial needs. Contact us today!

Pressure/Vacuum Relief Valves are utilized extensively in bulk storage tanks, which includes fixed roof tanks that have floating covers to reduce the loss of evaporation. The Valves stop the accumulation of excessive vacuum or pressure that can cause the system to become unbalanced or harm the vessel used for storage.

The levels of vacuum and pressure are controlled by springs or pallets that are weighted and are able to be combined to give the needed pressure and vacuum settings.

It is normal to mix spring and pallet systems into one piece i.e. tension settings need a spring segment while vacuum settings utilize using the pallet technique.

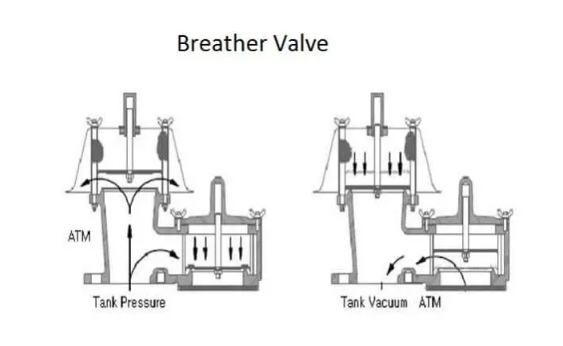

Breather Valve

Why use Breather Valves?

Breather Valve Breather Valve can be described as a safety device that is mounted in a nozzle opening at the top of an atmospheric storage tank with a fixed roof. tank. Its main purpose is to safeguard the tank from rupture or collapsing.

In the absence of an opening or a closed opening that is controlled, a roof atmospheric tank could break in the face of increasing pressure due to inflowing fluid into it, or due to the vapor pressure fluctuations due to extreme thermal changes. The implosion, or collapse of a tank, happens when the process of pumping out is completed or when the temperature changes.

As the liquid level drops as the liquid level decreases, the vapor pressure decreases to less than atmospheric pressure. This condition of vacuum is able to be cured by a controlled opening of the tank. In other words the tank has to breathe to reduce the risk of rupture or collapsing.

In light of its primary purpose due to its primary function, due to its primary function, this Valve is referred to as Breather Valve. The selection of Valves should be conforming to American Petroleum Institute Standard API 2000 or any other standard that is applicable.

What is the procedure by which Breather Valves operate?

The vast majority of tanks in the atmosphere require venting devices that permit large amounts of vapor to be released at very low pressures. The typical set pressure is measured in inches of pressure in the water column in both positive and vacuum conditions.

This is because the majority of big storage tanks are built with a small maximum allowable working pressure. These tanks are usually large-volume welded vessels that are constructed according to the API 650 standard. To be able to handle huge volumes and low pressures These Valves come with ports that are larger in size than the inlet or nozzle connection.

But, when choosing an appropriate established pressure Valve’s weight-loaded MAWP of the operation should be at least double the set pressure required to achieve the best flow. When the MAWP falls lower than 100% of the set required and the Valve could be bigger in dimension than is normal.

The potential for Valve chatter, as well as increased diaphragm and seat wear could occur if less than 20% pressure is permitted. In simple terms the Vacuum or Pressure Valve is not the same as a high-pressure Safety Relief Valve and shouldn’t be constructed with 10 20 percent or 20% above pressure.

When you are determining the size of the Pressure or Vacuum Valve look up the manufacturer’s flow curves and ensure that there is enough overset pressure.